Product Introduce

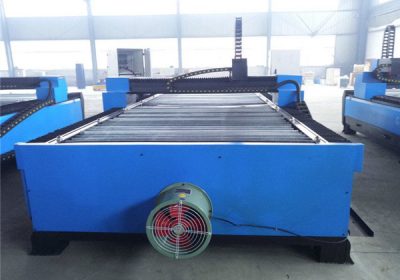

The production of Table CNC Plasma Cutting Machine, is specially used for sheet metal blanking of nc equipment. Can realize to all kinds of metal materials Under the press any graphic material cutting. Cut mouth roughness can be up to 25 (del) 3, after cutting machine is cutting surface usually don't need to do a surface processing. Has a high degree of automation, easy to use, high precision, high reliability, low price and maintenance is very easy to operate, and other advantages, is widely used in automobiles, Ship, space of various kinds of machinery manufacturing for sheet metal blanking cutting.

Features of Table Plasma Cutting Machine:

#1).The beam uses light structural design,with good rigidity structure, light deadweight and small movement inertia.

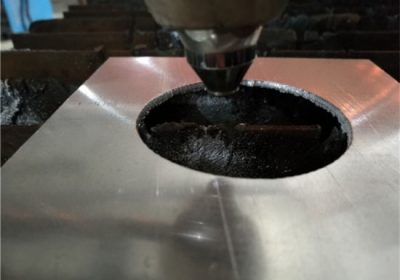

#2). The gantry structure, Y axis used dual-motor dual-driven system, X, Y, Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

#3).Completely solve the traditional manual processing methods. Improve the efficiency of several times.

#4). Cutting mouth is small, tidy,and avoid a second dressing processing.

#5). It can apply to iron sheet, the aluminium sheet, the galvanized sheet, hundred steel plates, metal plates and so on.

#6). High cutting speed, high precision, and low cost.

#7). The numerical control system disposes high, the automatic striking arc, the performance is stable.

#8). Support Wentai , ARTCAM softwares, Type3 produce standard G code way document, also can change software to read AUTOCAD softwares produce DXF form documents.

Product Character

Desktop CNC cutting machine is a kind of high-speed, precision CNC plasma cutting machine. Use the module structure, installation fast and convenient. Can smoking and table, in order to meet the requirements of environmental protection. 2, bilateral drive and mechanical precision, ensure the accuracy of cutting and precision. 3, the working width of 2000 mm, 6000 mm maximum working length can be up to 12 m/min , concentration of workbench (30 mm maximum cutting thickness)